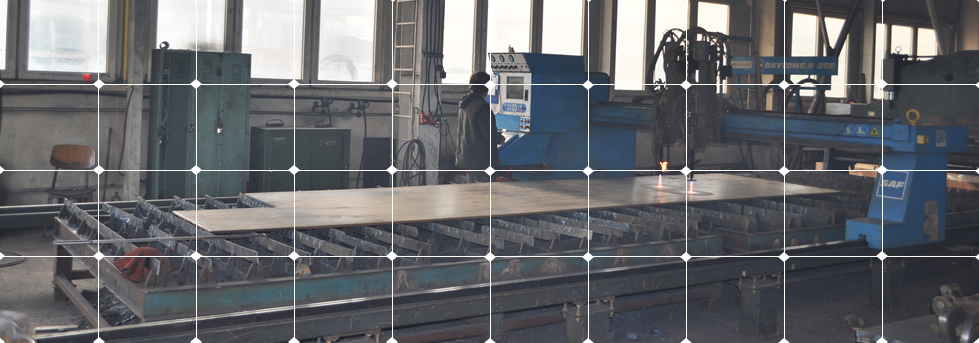

Metal Structures

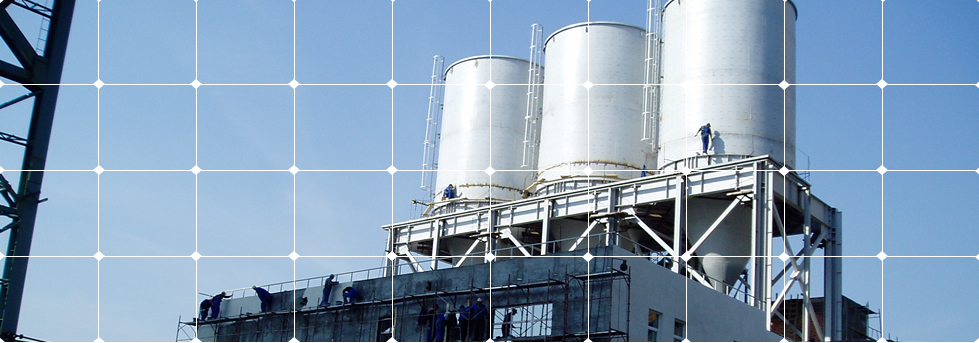

The products shown previously are a very small segment of the company’s ability to also deal with the range of works, as well as any other one upon order. As the welded structures are part of our basic production, all attention was directed towards the development and organisation of all technological processes competing to their achievement.

The products shown previously are a very small segment of the company’s ability to also deal with the range of works, as well as any other one upon order. As the welded structures are part of our basic production, all attention was directed towards the development and organisation of all technological processes competing to their achievement.

Thus, the following activities were organised:

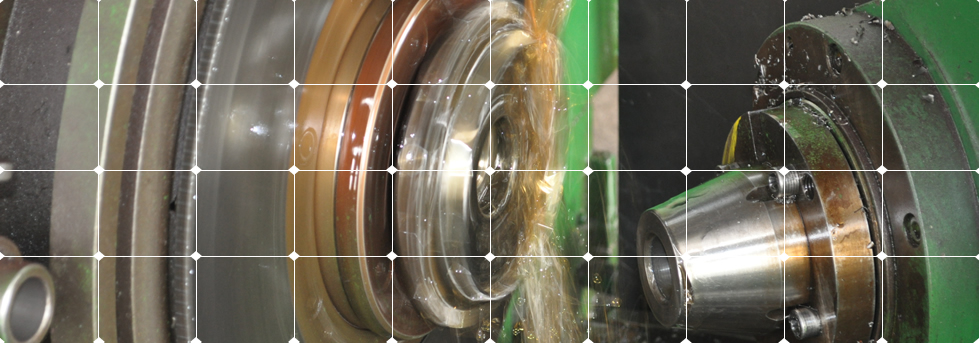

1. defectoscopic testing of destructive and non-destructive welds

2. procurement of advanced welding machines like FRONIUS, VARIO SYNERGIC 400

3. organisation of the work places and authorisation of welds in ISCIR and ISIM systems of Timisoara

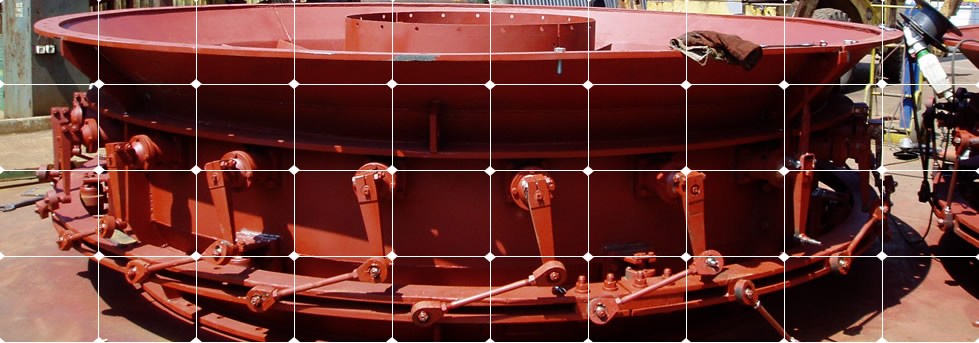

4. design/execution of welding device

5. control of deformations and their thermal recovery

6. analysis of the construction documentation and defining all technological implications to make the product, as well as the assessment of production costs

7. the inspection points have been defined in the manufacturing cycle, in order to avoid the nonconformities of any kind

By using all of the above, a better use of the capacities and work force were observed, which resulted in a substantial decrease in costs and technological utilities.

Role of recycled packaging container