Special Machining Processes

In order to achieve the desired productivity and a quality described by the product standards, the company has invested and continues to take into account new capacities in CNC system.

In order to achieve the desired productivity and a quality described by the product standards, the company has invested and continues to take into account new capacities in CNC system.

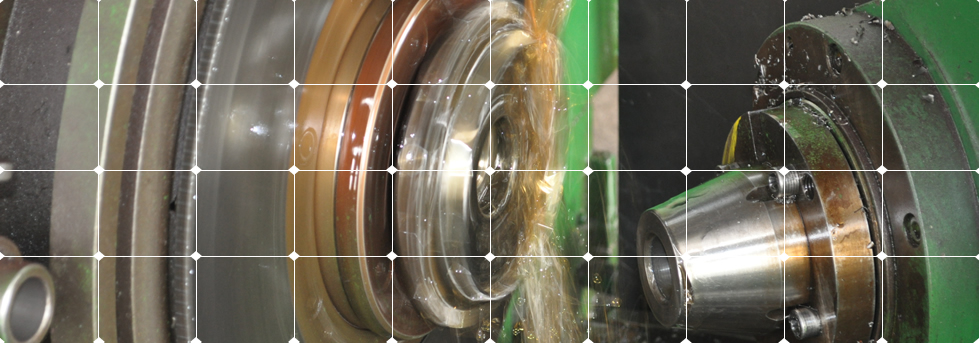

Thus, technological operations have been implemented, as follows:

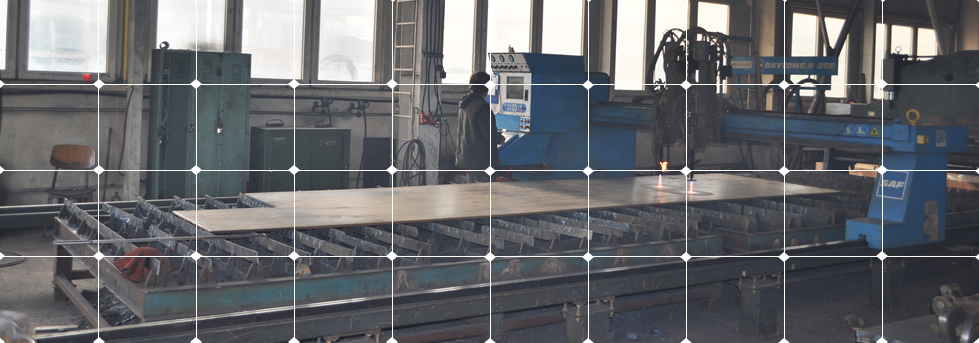

1.. oxy-fuel cutting of thick plates in numerical control system, the maximum cutting capacity for steels 2500x6000mm and a thickness of 200mm

2. . plasma cutting with numerical control, the system can cut materials such as: steels, stainless steel, aluminium and aluminium alloys. The maximum cutting capacity is of 2500x6000mm and a thickness of 35mm, the KOIKE machine - Japan. This cutting process with the two components has required a thorough technical analysis for the investment to provide the productivity and quality conditions of the shapes and sizes.

3. machining processes by cutting on CNC machines, this technological activity has been developed for milling and turning, with a timid beginning which, by the experience gained and results obtained, enabled the company to have a plan of new procurements in the field of turning in order to expand the dimensional range to cover the needs. Thus, we currently use for milling two CNC machines, like: HITACHI-SEIKI MV50 –Japan and OKUMA MB46-VAE –Japan, for the ranges in the reference system xyz 1000x500x450mm. Turning on the CMZ-TBI 450 machine for the range 450/300mm and distance between tops of 500mm.

For the processes shown here, the following activities have been developed:

For the processes shown here, the following activities have been developed:

a. design, programming in CNC system..

b. personal training for service and maintenance.

c. organisation and homologation of software with measurements and dimensional confirmation.